대한민국을 대표하는 제 104호

최은모 기능한국인입니다.

최은모

2015년 10월

-

• 선정호104호

-

• 분야제조업

-

• 소속

-

• 주요생산품목자동화 기계

학력사항

- • 조선이공대학교 기계과 (1984년)

- • 숭신공업고등학교 기계과 (1978년)

주요경력

- • 2004년~현재 (주)무진서비스 / 대표

- • 1988년~2003 무진서비스 / 대표이사

- • 1977년~1987년 화천기계공업(주) / 기술영업팀

특허 및 실용신안

- • 제10-1096773호“극판자동적재장치”

- • 제10-1309132호“배터리박스 내에 셀을 로딩하기 위한 장치 및 방법”

- • 제10-1454481호“배터리용 캐스트 온 스트랩 몰드의 순환식 냉각 구조”

-

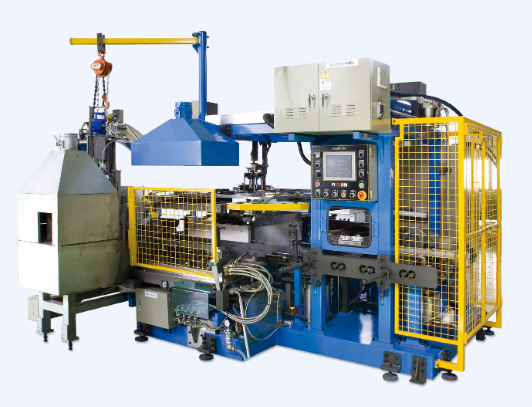

COS IO1. General teatures & merit- Cycle Time : Approx. 3 Batteries / Min. based on LN3 Battery- Semi Automatic Operation . Manual : Loading / Unloading Station . Auto : Aligning, Lug brushing, Fluxing, Drying and Molding Station- Battery type Changeover : Approx. 15 minutes 2. Machine details- Applicable battery size : L186 - 525, W125 - 278, H170 - 250 (in mm)- Air part : SMC- Main power . Motor : 1.5kW . Mold : 18kw . Melting pot : 24kW- Melting furnace : Electric furnace- Control PLC : MITSUBISHI, Touch screen : PROFACE or MITSUBISHI- Sensor : KEYENCE, OMRON, MITSUBISHI (USER OPTION)- Approx. size & weight : L3,070 × W3,780 × H2,500mm / 6,000kg 3. Detail information of each process• 1st Station (Loading) - Manual loading of plates into jig box• 2nd station (Aligning, Brushing, Fluxing and Drying) - With vibration table ass’y & automatic top lug align unit - Using servo system for adjusting the height of the vibration table according to the various height of plates.• 3rd station (Molding) - Using servo motor for precise control of depth of lug in strap and also of the movement (timing of dipping and dipping speed)• 4th station (Unloading) - Lifting up plate groups from jig box for operator to take them out more easily. - Two types of Jig Boxes; . If plate group thickness is less than 75mm → 6 cells / cycle (3 batteries / min) . If plate group thickness is more than 75mm → 3 cells / cycle (1.5 batteries / min) 4. UtilityStandard electrical power220V / 380V / 440V * 3-phase * 50 / 60Hz(USER OPTION)Compressed air5 ~ 6kg / ㎠Cooling water2 ~ 4kg / ㎠

COS IO1. General teatures & merit- Cycle Time : Approx. 3 Batteries / Min. based on LN3 Battery- Semi Automatic Operation . Manual : Loading / Unloading Station . Auto : Aligning, Lug brushing, Fluxing, Drying and Molding Station- Battery type Changeover : Approx. 15 minutes 2. Machine details- Applicable battery size : L186 - 525, W125 - 278, H170 - 250 (in mm)- Air part : SMC- Main power . Motor : 1.5kW . Mold : 18kw . Melting pot : 24kW- Melting furnace : Electric furnace- Control PLC : MITSUBISHI, Touch screen : PROFACE or MITSUBISHI- Sensor : KEYENCE, OMRON, MITSUBISHI (USER OPTION)- Approx. size & weight : L3,070 × W3,780 × H2,500mm / 6,000kg 3. Detail information of each process• 1st Station (Loading) - Manual loading of plates into jig box• 2nd station (Aligning, Brushing, Fluxing and Drying) - With vibration table ass’y & automatic top lug align unit - Using servo system for adjusting the height of the vibration table according to the various height of plates.• 3rd station (Molding) - Using servo motor for precise control of depth of lug in strap and also of the movement (timing of dipping and dipping speed)• 4th station (Unloading) - Lifting up plate groups from jig box for operator to take them out more easily. - Two types of Jig Boxes; . If plate group thickness is less than 75mm → 6 cells / cycle (3 batteries / min) . If plate group thickness is more than 75mm → 3 cells / cycle (1.5 batteries / min) 4. UtilityStandard electrical power220V / 380V / 440V * 3-phase * 50 / 60Hz(USER OPTION)Compressed air5 ~ 6kg / ㎠Cooling water2 ~ 4kg / ㎠ -

PARTITION HOLE PUNCHING MACHINE1. General teatures & merit- Cycle Time : Approx. 4.5 Batteries / Min. of LN3 Battery- Easy and quick changeover in touch screen- Using linear motion guide for stable and accurate hole punching- Automatic collecting of punched chip by suction into box 2. Machine details- Applicable battery size : L185 - 410, W125 - 180, H170 - 250 (in mm)- Air part : SMC- Frame & Cover material : SS41, SKD11, MC, SM45C- Main power : 9kW- Control PLC : MITSUBISHI- Touch screen : PROFACE or MITSUBISHI- Approx. size & weight : L2,800 × W1,300 × H2,500mm / 2,100kg 3. UtilityStandard electrical power220 / 380 / 440V * 3-phase * 50 / 60Hz (USER OPTION)Compressed air5 ~ 6kg / ㎠

PARTITION HOLE PUNCHING MACHINE1. General teatures & merit- Cycle Time : Approx. 4.5 Batteries / Min. of LN3 Battery- Easy and quick changeover in touch screen- Using linear motion guide for stable and accurate hole punching- Automatic collecting of punched chip by suction into box 2. Machine details- Applicable battery size : L185 - 410, W125 - 180, H170 - 250 (in mm)- Air part : SMC- Frame & Cover material : SS41, SKD11, MC, SM45C- Main power : 9kW- Control PLC : MITSUBISHI- Touch screen : PROFACE or MITSUBISHI- Approx. size & weight : L2,800 × W1,300 × H2,500mm / 2,100kg 3. UtilityStandard electrical power220 / 380 / 440V * 3-phase * 50 / 60Hz (USER OPTION)Compressed air5 ~ 6kg / ㎠ -

HOT MELT APPLICATOR1. General teatures & merit- Cycle time : Approx. 5 Batteries / Min. of LN3 Battery- Machine heats solid adhesive material and converts it into liquid status and apply hot melt material on plate groups. This prevents growing of expanded type plate and damages on plates due to vibration.- Easy Changeover using screw and handle though manual method (Fully automatic system available)- Applying hot melt material on container bottom surface and each plate group by using 2 or 3 nozzles- Using limit switch so no need to changeover for different cell distance. (Quick changeover on touch screen if applying servomotors - Option) 2. Machine details- Applicable Battery Size : L185 - 410, W125 - 180, H170 - 250 (in mm)- Air part : SMC- Main power : 10kW- Control PLC - MITSUBISHI- Approx. size & weight : L1,580 × W1,260 × H1,900mm / 1,000kg 3. UtilityStandard electrical power220 / 380 / 440V * 3-phase * 50 / 60Hz (USER OPTION)Compressed air5 ~ 6kg / ㎠

HOT MELT APPLICATOR1. General teatures & merit- Cycle time : Approx. 5 Batteries / Min. of LN3 Battery- Machine heats solid adhesive material and converts it into liquid status and apply hot melt material on plate groups. This prevents growing of expanded type plate and damages on plates due to vibration.- Easy Changeover using screw and handle though manual method (Fully automatic system available)- Applying hot melt material on container bottom surface and each plate group by using 2 or 3 nozzles- Using limit switch so no need to changeover for different cell distance. (Quick changeover on touch screen if applying servomotors - Option) 2. Machine details- Applicable Battery Size : L185 - 410, W125 - 180, H170 - 250 (in mm)- Air part : SMC- Main power : 10kW- Control PLC - MITSUBISHI- Approx. size & weight : L1,580 × W1,260 × H1,900mm / 1,000kg 3. UtilityStandard electrical power220 / 380 / 440V * 3-phase * 50 / 60Hz (USER OPTION)Compressed air5 ~ 6kg / ㎠ -

BATTERY PALLETIZING MACHINE1. General teatures & merit- Cycle Time : Up to 6 batteries / Min. based on LN3 battery- Full automatic operation in each station2. Machine details- Applicable plate size : L185 - 410, W125 - 182, H175 - 230 (in mm)- Air part : SMC, FESTO(USER OPTION)- Main power : 16kW- Control PLC : MITSUBISHI, Touch screen : PROFACE or MITSUBISHI USER OPTION : ALLEN BRADLEY, SIEMENS and other Brands- Sensor : KEYENCE, OMRON, MITSUBISHI (USER OPTION)- Approx. size & weight : L5,400 x W5,200 x H2,300mm / 7,000kg3. Detail information of each process• 1st Station : Intermediate plate(paper sheet) supplying part Using a vacuum compression pad of robot• 2nd Station : Pallet supplying part / buffer part for intermediate plate(paper sheet)• 3rd Station : Robot part Battery palletizing and supplying intermediate plate(paper sheet)• 4th Station : Battery palletizing and discharging batteries4. UtilityStandard electrical power220V / 380V / 440V * 3-phase * 50 / 60Hz(USER OPTION)Compressed air5 ~ 6kg / ㎠

BATTERY PALLETIZING MACHINE1. General teatures & merit- Cycle Time : Up to 6 batteries / Min. based on LN3 battery- Full automatic operation in each station2. Machine details- Applicable plate size : L185 - 410, W125 - 182, H175 - 230 (in mm)- Air part : SMC, FESTO(USER OPTION)- Main power : 16kW- Control PLC : MITSUBISHI, Touch screen : PROFACE or MITSUBISHI USER OPTION : ALLEN BRADLEY, SIEMENS and other Brands- Sensor : KEYENCE, OMRON, MITSUBISHI (USER OPTION)- Approx. size & weight : L5,400 x W5,200 x H2,300mm / 7,000kg3. Detail information of each process• 1st Station : Intermediate plate(paper sheet) supplying part Using a vacuum compression pad of robot• 2nd Station : Pallet supplying part / buffer part for intermediate plate(paper sheet)• 3rd Station : Robot part Battery palletizing and supplying intermediate plate(paper sheet)• 4th Station : Battery palletizing and discharging batteries4. UtilityStandard electrical power220V / 380V / 440V * 3-phase * 50 / 60Hz(USER OPTION)Compressed air5 ~ 6kg / ㎠